As leaders in gas turbine silencing equipment since 1948, we receive questions every day about the components, the equipment, and even the industry itself.

Many people work within some aspect of the gas turbine industry, without knowing exactly how gas turbine plants actually work—especially since natural-gas-fueled power plants have taken off in recent years. Knowing this can help significantly, as you’ll have a better understanding of your needs, your focus, your customers and suppliers, and your job.

How Gas Turbines Work

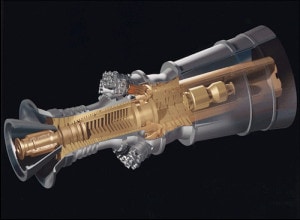

Gas turbines, increasingly in use in power plants throughout the country, are complex

machines, but can be broken down into three main components:

- The Compressor – This draws air into the engine and then pressurizes it, feeding it into the combustion chamber at high speeds—hundreds of miles per hour.

- The Combustion System – Consisting of a ring of fuel injectors that feed the fuel into the combustion chambers, the fuel and air mix and are burned at temperates of over 2,000 degrees F. A high-pressure, high-temperature gas stream then enters, expanding through the turbine.

- The Turbine – Here, intricately alternating rotating and stationary blades cause combustion gas to expand, spinning the rotating blades which are simultaneously driving the compressor to draw air into the combustion system, and spinning a generator to produce electricity.

There are two types of land-based gas turbines—heavy frame engines and aero derivative engines—operating at low pressure ratios and high compression ratios, respectively. In either case, a turbine’s furl-to-power efficiency is largely based on its operating temperatures, with higher temperatures generally meaning greater efficiencies.

Today’s Gas Turbines

Recently, previous turbine temperature limitations have been broken through the use of advanced materials and technologies, much of which was achieved through the Department of Energy’s advanced turbine program. By boosting temperatures by about 300 degrees, efficiency was boosted significantly—achieving efficiencies up to 60%.

As a result, gas turbines, and the plants they power, are better than ever, providing greater fuel efficiency with lower emissions, and promising even more success for the near future.